- The Importance of E-commerce Inventory Management

- Forecasting Demand Accurately

- Optimizing Stock Levels

- ABC Analysis & Stock Prioritization

- E-commerce Inventory Management Tools

- Preventing Stockouts and Overstocking

- Conclusion

- Frequently Asked Questions (FAQs)

Table of Contents

6 Effective Ways to Optimize Ecommerce Inventory Management

“Out of stock!”, this is the most dreadful message a customer faces at the end of the checkout process. It might lead to a loss of sales and put business at risk of customer trust.

You can maintain your sales with effective e-commerce inventory management.

On the other hand, overstocking can be just as detrimental. Excess inventory ties up valuable capital, eats up storage space, and can lead to dead stock that becomes obsolete or unsaleable.

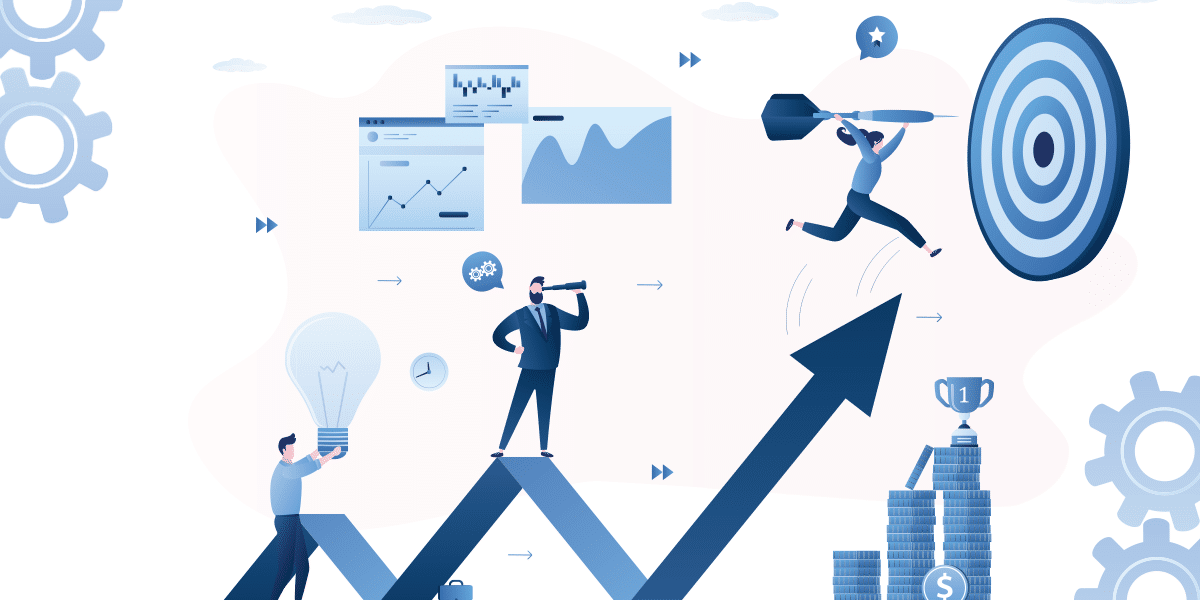

Whether you're a growing startup or an established online retailer, mastering e-commerce inventory management is essential for sustaining competitive advantage and driving growth.

Maintaining the right balance of stock levels can significantly impact sales, operational efficiency, and customer satisfaction.

In this blog, we will explore 6 effective ways to optimize your e-commerce inventory management.

The Importance of E-commerce Inventory Management

Efficient e-commerce inventory management isn't a luxury - it's the backbone of a thriving online business. It directly impacts every aspect of your customer experience, from product availability to order fulfillment speed.

Happy Customers, Loyal Customers: if your inventory is insufficient it could lead to losing a potential sale and customer trust.

Consistent stockouts can lead to frustration, ultimately driving customers to competitors. It is important to have the products in stock when customers are ready to buy fostering satisfaction and loyalty, keeping them coming back for more.

Lost Sales and Missed Opportunities: Stockouts aren't just a customer inconvenience; they represent lost revenue for your business. In the current data-driven world, online search engines often penalize websites with low stock availability.

This can make it harder for potential customers to discover your products. This hinders the overall sales potential.

Cash Flow & Profitability: Inventory represents a significant investment for any e-commerce business.

Inefficient e-commerce inventory management, like overstocking ties up valuable capital that could be used for marketing or product development.

Additionally, it incurs storage costs and risks products becoming obsolete or damaged, leading to write-offs and further financial losses.

Operational Efficiency & Scalability: Streamlined e-commerce inventory management systems empower you to fulfill orders quickly and accurately.

This translates to faster delivery times, improved customer satisfaction, and a positive brand image. By optimizing stock levels and forecasting demand effectively, you'll be better prepared to handle fluctuations in sales.

This agility is crucial for scaling your e-commerce business and achieving sustainable growth.

Forecasting Demand Accurately

Accurate demand forecasting of e-commerce inventory management is the best skill to acquire. This involves predicting future customer demand for your products.

By utilizing e-commerce inventory management software you can make informed decisions about inventory levels.

Data-Driven Inventory Decisions: Demand forecasting goes beyond guesswork. It utilizes historical sales data, seasonal trends, and marketing campaign insights to paint a clearer picture of future demand.

Armed with this knowledge, you can make data-driven decisions about how much stock to order, when to order it, and how to optimize e-commerce inventory management across different sales channels.

Preventing Stockouts and Lost Sales: Without leveraging e-commerce inventory management software for accurate forecasting you can risk losing sales for a particular product right before the holiday season.

Demand forecasting helps you anticipate these peaks and valleys in demand, ensuring you have enough inventory on hand to meet customer needs.

Optimizing Profitability: Overstocking may seem like a safe bet, but it can lead to a financial nightmare.

Excess inventory ties up capital, eats away at storage space, and can lead to dead stock that becomes obsolete or unsaleable.

Demand forecasting helps you strike the perfect balance, ensuring you have enough stock to fulfill orders without unnecessary inventory that drains your profits.

Improved Product Launches & Promotions: Demand forecasting plays a vital role in planning for the launch of a new product and promotional campaigns.

You can anticipate the potential demand for a new product and ensure you have adequate stock.

Similarly, for upcoming promotions, demand forecasting allows you to predict the potential sales increase and adjust inventory levels accordingly.

Building a Responsive Supply Chain: Accurate demand forecasts empower you to collaborate effectively with suppliers.

By providing them with anticipated demand insights, you can ensure they have the resources available to meet your future needs.

This fosters a strong supplier relationship and minimizes the risk of disruptions in your supply chain.

Optimizing Stock Levels

A perfectly balanced, focused on staying centered is the ideal state for your e-commerce inventory.

Optimizing stock levels is about achieving a delicate balance between having enough products to meet customer demand and avoiding overstocking.

Understanding Demand Fluctuations: Not all products sell at a steady pace.

Seasonal trends, marketing campaigns, and even competitor actions can cause fluctuating demand.

By analyzing considering upcoming promotions or seasonal shifts, you can predict these fluctuations and adjust your stock levels accordingly.

Minimum Order Quantities (MOQs) vs. Ideal Order Quantities: Many suppliers impose minimum order quantities (MOQs) – the smallest amount a customer can purchase.

However, the ideal order quantity might be different. Balancing the cost-efficiency of larger orders with storage limitations and the risk of obsolescence is key.

The Power of Safety Stock: Safety stock is a buffer of inventory you maintain to guard against unexpected demand surges or delays in shipments.

Calculating the right amount of safety stock involves considering factors like lead times from suppliers, historical sales variations, and the criticality of the product.

ABC Analysis for Prioritizing Your Inventory: The ABC analysis is a powerful tool for categorizing your inventory based on its value and impact on your business.

ABC Analysis & Stock Prioritization

Not all products are created equal or sold equal. Some generate significant revenue and drive sales, while others contribute a smaller portion.

ABC analysis is a strategic approach to e-commerce inventory management that categorizes inventory based on its value and impact on the business. Here's how ABC analysis works:

Data Classification: The first step is gathering data on your inventory. This includes factors like annual unit sales, cost per unit, and total revenue generated by each product.

Calculating the Annual Value: Multiply the unit sales by the cost per unit to determine the annual value of each product in your inventory. This provides a clear picture of which products contribute the most to your overall revenue.

Categorizing Your Inventory: Once you have the annual value for each product, rank them from highest value to lowest value. Then, divide the total annual value of your inventory into three segments, for instance around 70/20/10.

- A Items (High Value): These represent the top 70% of your inventory's total value. ‘A’ items are typically the fast-selling, high-revenue generating products. These require the closest attention in terms of inventory control and prioritization.

- B Items (Medium Value): The middle 20% of your inventory value falls under ‘B’ items. These are medium-value, medium-selling products. A balance between cost-efficiency and ensuring availability is key for ‘B’ items.

- C Items (Low Value): The bottom 10% of your inventory value represents ‘C’ items. These are typically low-value, slow-selling products. Streamlined ordering processes and minimal safety stock are appropriate for ‘C’ items.

Benefits of ABC Analysis

Focused Inventory Management: By identifying the high-value ‘A’ items, you can allocate more resources towards their e-commerce inventory management. This might involve closer monitoring of stock levels, implementing stricter reorder points, or even considering higher safety stock levels to prevent stockouts.

Reduced Carrying Costs: ‘C’ items with their lower value and slower sales velocity, don't require the same level of inventory management attention. ABC analysis allows you to streamline ordering processes for ‘C’ items. This potentially reduces ordering frequency and minimizes storage space needs.

Improved Resource Allocation: ABC analysis empowers you to allocate your e-commerce inventory management resources more effectively. You can focus your expertise and manpower on the critical ‘A’ items. Implement efficient processes for managing the less impactful ‘B’ and ‘C’ items.

Suggested Reading : How to Choose Right Enterprise ecommerce Platform in 7 Steps

E-commerce Inventory Management Tools

Juggling spreadsheets and manual calculations is a nightmare when it comes to e-commerce inventory management. Fortunately, a wide range of e-commerce inventory management software solutions exist to automate tasks.

This empowers you to make data-driven decisions and revolutionize your inventory management.

Centralized Inventory Management: E-commerce inventory management software provides a central hub for all inventory needs.

You can track stock levels across different sales channels, warehouses, or fulfillment centers in real time, ensuring complete visibility and control.

Automated Inventory Replenishment: Manual reordering can be stressful.

E-commerce inventory management software automates the reorder process, generating purchase orders based on predefined minimum stock levels.

This ensures you never run out of stock while also preventing unnecessary overstocking.

Data-Driven Insights & Reporting: E-commerce inventory management software goes beyond basic stock tracking.

It provides reporting tools that offer valuable insights into your sales trends, product performance, and overall inventory health.

These insights empower to make informed decisions about product sourcing, pricing strategies, and future inventory planning.

Improved Order Fulfillment Accuracy: E-commerce inventory management software integrates seamlessly with your order fulfillment processes.

By providing real-time stock visibility, you can accurately pick, pack, and ship orders. This minimizes fulfillment errors and ensures a smooth customer experience.

Reduced Costs & Increased Efficiency: Investing in e-commerce inventory management software can lead to significant cost savings in the long run.

Reduced manual labor, streamlined processes, and minimized stockouts contribute to improved operational efficiency.

Some software offers features such as barcode scanning and warehouse management tools, further enhancing efficiency and accuracy.

Preventing Stockouts and Overstocking

The ideal state for your e-commerce inventory management is a state of equilibrium – having enough stock to satisfy customer demand without facing overstocking.

This delicate balance requires tackling, preventing stockouts and avoiding overstocking.

Preventing Stockouts

Lead Time Calculations: the time it takes for the supplier to deliver an order is a crucial factor when setting reorder points, the minimum stock level that triggers a new order. This ensures enough inventory to bridge the gap between placing an order and receiving it.

Safety Stock Management: Safety stock acts as a buffer against unexpected demand surges or delays in shipments. By calculating optimal safety stock levels based on historical sales variations, lead times, and product criticality, you can minimize the risk of stockouts.

Demand Forecasting & Alerts: Accurate demand forecasting helps to anticipate future sales trends. Combine this with automated inventory alerts that notify you when stock levels approach reorder points. This proactive approach ensures you don't get caught off guard by unexpected demand spikes.

Supplier Communication: Maintaining open communication with suppliers is vital. Inform them of any upcoming promotions or anticipated sales increases that might impact demand. Additionally, discuss any potential disruptions in supply chain that could affect your inventory levels.

Avoiding Overstocking

Maximum Inventory Levels: Set realistic maximum inventory levels for products. This helps prevent overstocking, especially for slow-selling items. Regularly review and adjust these levels based on sales data and market trends.

ABC Analysis & Prioritization: ABC analysis helps to categorize inventory based on value and sales velocity. Focus on optimizing stock levels for your high-value ‘A’ items, while implementing leaner inventory management practices for low-value ‘C’ items.

Sales & Promotions Planning: Plan sales and promotions strategically, taking into account the current inventory levels and lead time. Avoid overstocking in anticipation of a promotion, as it can risk getting stuck with excess inventory if the promotion doesn't perform as expected.

E-commerce Inventory Management Software: It plays a crucial role in preventing overstocking. These tools provide real-time stock visibility, sales data analysis, and forecasting capabilities. This allows you to make data-driven decisions about ordering quantities.

Conclusion

E-commerce is a competitive market hence, efficient e-commerce inventory management is the key to success in your business.

By leveraging data analytics and ABC analysis you can optimize e-commerce inventory management.

Utilizing e-commerce inventory management tools help to prevent stockouts, avoid overstocking, and ultimately ensure the right products are in stock at the right time.

This keeps your customers happy and the business thriving.

Remember, this is an ongoing process, so adapt the strategies as needed to maintain inventory equilibrium and propel your e-commerce business forward.

Don’t forget to implement the 6 effective ways to optimize e-commerce inventory management as discussed above.

Suggested Reading : Maximizing ROI: Strategies for Enterprise eCommerce Growth

Frequently Asked Questions (FAQs)

What are the biggest challenges to optimize e-commerce inventory management?

To optimize e-commerce inventory management involves keeping track of stock across various locations and maintaining accurate levels to avoid stockouts or overstocking.

It also requires forecasting demand accurately and managing supplier relationships effectively.

How can I optimize e-commerce inventory management for forecasting?

For better inventory forecasting, analyze past sales data, consider upcoming promotions and seasonal trends, integrate data from multiple channels, and leverage inventory management software with advanced forecasting features.

What are the benefits of using ABC analysis for e-commerce inventory management?

ABC analysis prioritizes your stock control efforts by classifying inventory based on value and impact.

This helps reduce carrying costs for low-value items, improve resource allocation, and gain valuable data for informed sourcing and pricing decisions.

Table of Contents

- The Importance of E-commerce Inventory Management

- Forecasting Demand Accurately

- Optimizing Stock Levels

- ABC Analysis & Stock Prioritization

- E-commerce Inventory Management Tools

- Preventing Stockouts and Overstocking

- Conclusion

- Frequently Asked Questions (FAQs)